Atelier

Having selected the leather carefully, nailed and hammered, we have created each shoe with its own story in mind. It has made an impression on us and so it will on you. This note isn’t for you, it is for them.

The journey of design and production in our atelier, in which only a limited number of hand-made shoes are made...

Designing a shoe does not just begin with thinking about a model, choosing its last and heel. At least, it’s not like that for me. I get excited and inspired when I see a novel material. This could be anything like fabric, leather or furniture material. While I focus on this material that I cherish, I evaluate its quality, forms of utilization and I test it. I aim for each shoe to be both comfortable and chic.

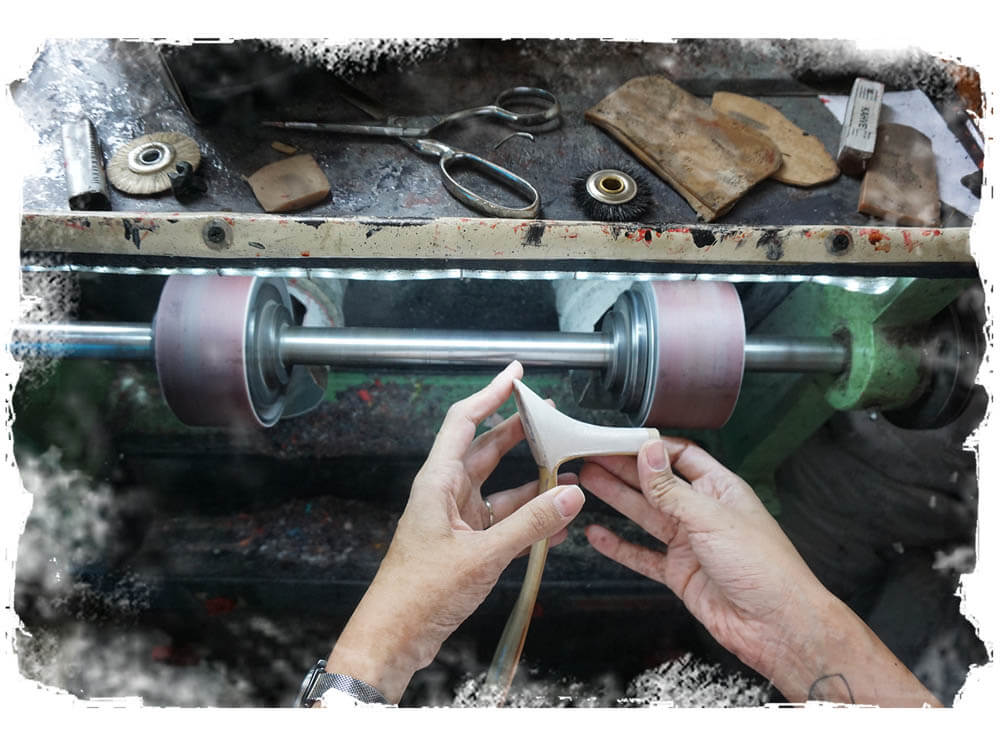

Each season, I reuse the violin peg as an accessory in order to associate my designs with my occupation. I don’t worry about the trends. I enjoy reproducing some classical models in my own style in every few seasons.

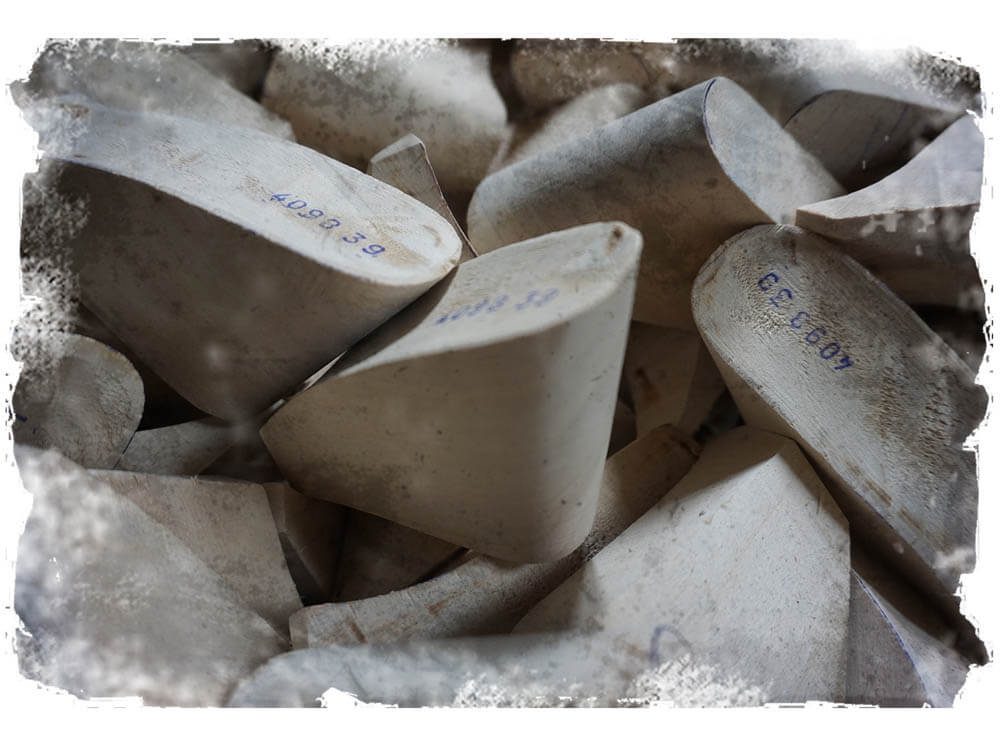

When a new model takes its final form in my mind, I draw it on the chosen last including its details like the stitching. Afterwards, my modelist creates the stamp. I decide on the leather or fabric to be used for each part, the type and main color of the sole and then come up with different color options. I also decide on the type and color of the laces/zippers, thickness of thread and color of the stitches. If the model is going to be heeled, I choose its heel. Sometimes I design special heels to be made out of wood and hand it in to our heel artisan.

The rest is at the hands of our artisans;

Our cutter cuts the material by using the stamps. If the material to be cut is fabric, then its direction and pattern is used as a base. If the material to be cut is leather, the part to be used is carefully chosen, since not all leather parts are convenient for each part of a shoe. Our sayacı? combines the cut out parts according to their stitching and combination possibilities. The final product is called the “upper”.

At this stage, we do not use any machinery. The sewn upper is stretched by hand until it takes the form of the last and nailed to the last itself. That’s why the inner parts of our artisans’ knees are severely calloused. The upper stays in the last for two days in order to fully gain its form.

Later on, the sole is hot-glued under the last by hand and the last is taken out of it. At the final stage of production, the insole is placed inside the shoe; its accessories are attached, cleaned and boxed.